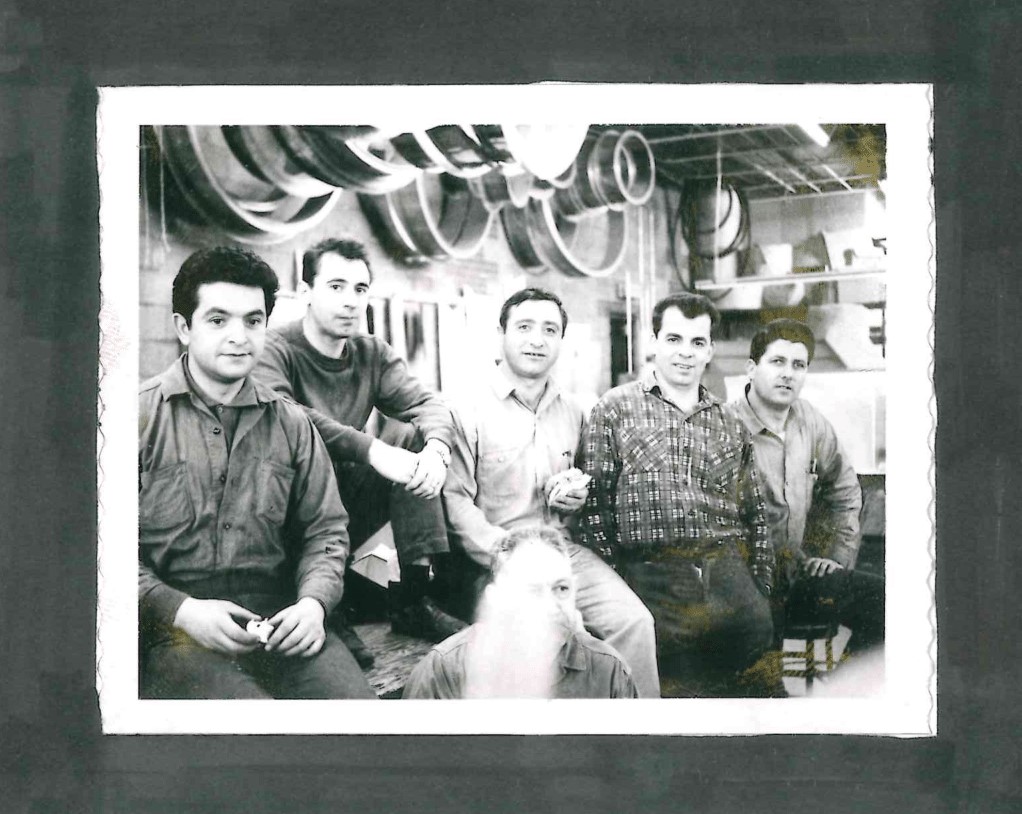

A “mom and pop” skylight company was established in 1980, founded by innovative entrepreneurs and Italian immigrants, Sam and Teresa Ferrazzo. Their ambitions were to create a skylight company that would thrive through the ages and push the envelope of daylighting possibilities. Their philosophy extended past simply providing quality skylights to the public, but rather provide a higher level of design support services and a level of customer care that was not easily found in the roofing and construction industry at the time. So, Artistic Skylight Domes was born and the journey began. The harsh routine of intaking orders in the morning, manufacturing product during the day, and delivering to customers in the evening began. The struggles of entrepreneurship was all too real for our founders.

About Us

Cool Timeline

Shortly after the conception of Artistic Skylight, quickly followed our very first location in Mississauga on Nashua Dr. Our humble 3,200sqft. facility served as the launching point of what has become an amazing journey. During this time period, our manufacturing capabilities were limited to curb mounted and self flashing skylights comprised of aluminum and acrylic components. Some miscellaneous skylights were also produced but not yet a mainstream product offering.

In only 5 years since the start of the company, Artistic Skylight® is taking its first major improvement to operations by moving to an upgraded facility in Rexdale, ON. Our 5000sqft. building located at Haas Rd. in Rexdale, ON. will serve the company for the next 12 years as a place to grow and build our reputation as a premier skylight manufacturer.

As the demand for larger spanned skylights become increasingly popular, the development of our first revision of our cold-formed profiles came to be. With these profiles, they allow for a structurally sound product that can accommodate large roof openings without additional supports or building restructuring. As an added benefit, these profiles would allow for easier manufacturing of our newly offered barrel vaulted continuous modular skylights – capable of covering infinite length dimensions.

With improvements to chemical compounds to PVC (Polyvinyl Chloride) materials, its usage quickly became a popular choice for all fenestrations. The final results produced higher thermal performance and resistance to mold and rotting than its all-aluminum or wood counterparts. This became the basis for our curb mounted skylights – and later on our self flashing skylights. Today, our PVCCM product line is by far our most popular product with an all PVC curb frame to create the optimal thermal break for your skylight.

Our biggest product line expansion has started and with the introduction of glass glazing starting to become the preferred choice for glazing, this fuels innovation into our current lineup of Glass Skylights and Architectural Structural Glass Pyramid Skylights. With the increasing trend of pushing the envelope for aesthetically beautiful skylight structures, our line of Circular Unit Skylights became an immediate success for the industry – providing a daylighting experience that is satisfying without performance sacrifice. To present, day Artistic Skylight Domes is one of the few manufacturers of circular shaped skylights. The creation of these new products has led to opportunities for the firm to explore new commercial, large-scale projects cementing our place among the elite skylight manufacturers.

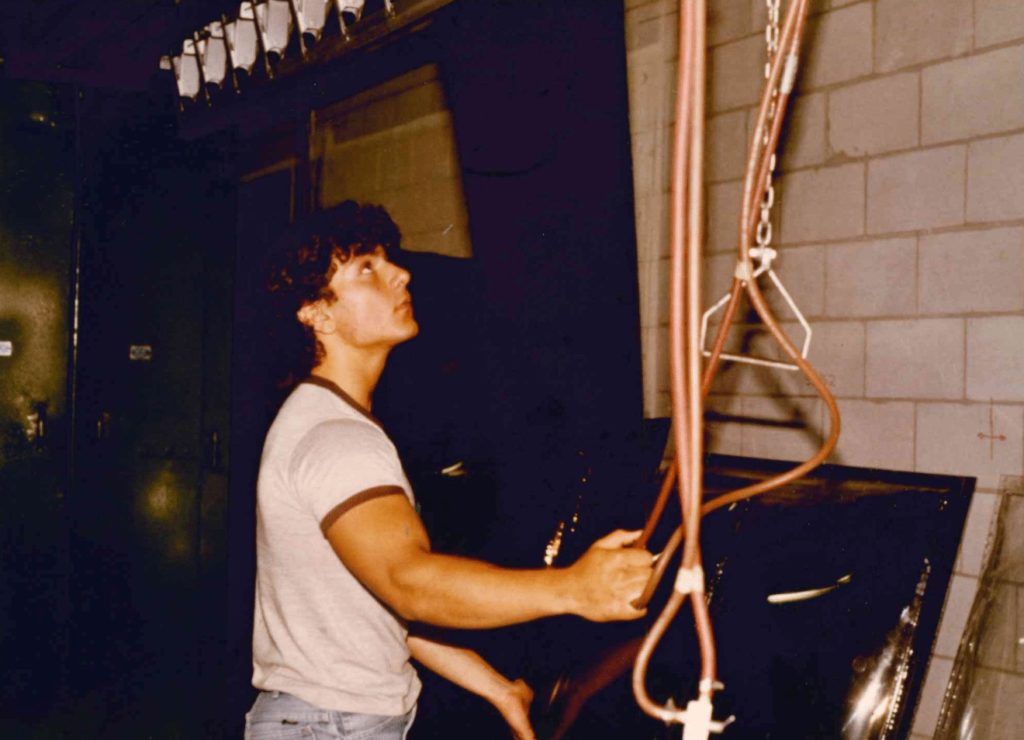

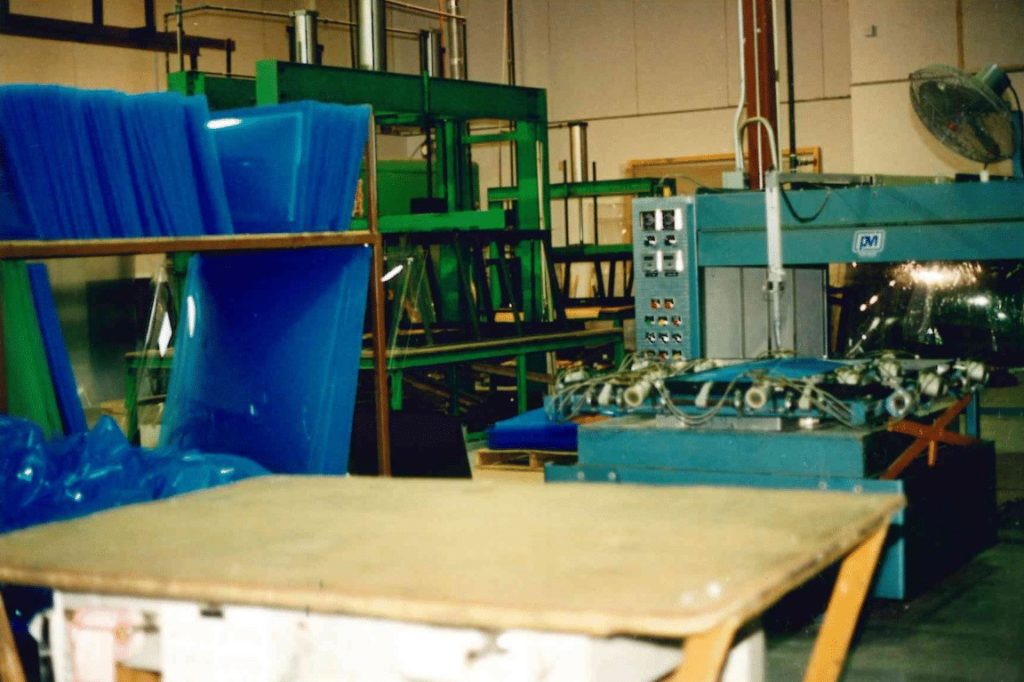

With the evolution of our curb mounted skylights and a boom in skylight popularity, demand for larger quantities of product quickly grew. To keep up with demand of our acrylic dome skylights, the introduction of automatic thermo-forming was brought to the production floor. A flat sheet of acrylic is placed into the bed of the machine, clamped and heated to optimal forming temperatures. The melted sheet is then pulled over a mold and free formed into our iconic dome shaped skylight. Our first thermo-former was small but mighty and has evolved into many more, larger capacity machines over the decades capable of ever expanding amounts of formed acrylic domes per work shift.

Into our 17th year of service the Artistic Skylight Domes team steadily grew to meet an ever expanding demand. With the rapid expansion through the early stages of the company, a need for a larger work space was required. Our third location was in the form of a 14,000sqft. building located in Rexdale, ON. at 2 Guided Crt. and would be called home for the next 2 decades. Many of our customers today will still remember this factory as this is where the company saw its largest growth. Large factory expansion coupled with new cutting edge machinery, wider ranges of product lines and higher quality products all amending to the modern day success of a once small sized company.

Our current iteration of our barrel vaulted skylights was developed with the revision of our coldform profiles that has led to improved thermal performance, improved manufacturing and increased structural integrity. These profiles better aligned with updated aluminum extruding techniques, customer input on our current product and ease of manufacturing and fabrication further showcasing our commitment to high quality finished product.

With newer trends in the aluminum and fenestration world, led to the introduction of what is now know as our Commercial Bronze aluminum frame finish. Due in part to the TIG welding process that is used for all mill finish aluminum the development of our modern day corner key system was created. This would allow seamless and aesthetically pleasing corner connections of our painted frames. Today, we offer our frames in 3 main finishes (Mill Finish, Commercial Bronze, Matte Black) and can colour match any colour required for your project.