About Us

Artistic Skylight History Timeline

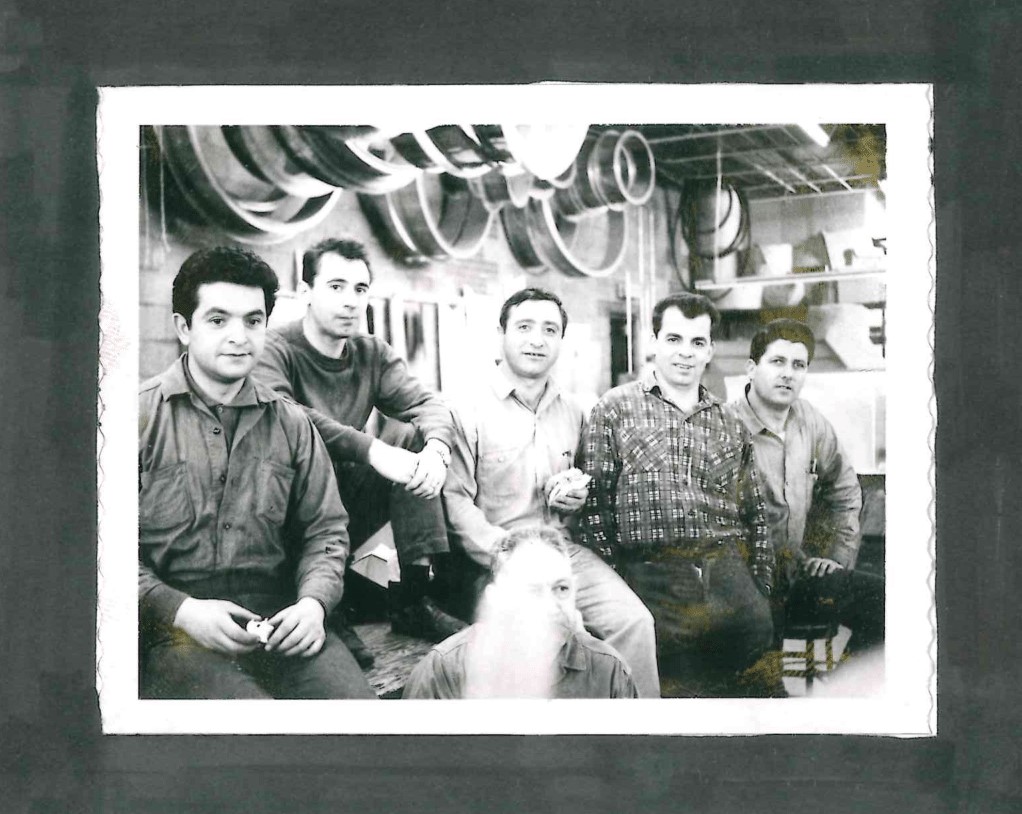

The Beginning

A “mom and pop” skylight company was established in 1980, founded by innovative entrepreneurs and Italian immigrants, Sam and Teresa Ferrazzo. Their ambitions were to create a skylight company that would thrive through the ages and push the envelope of daylighting possibilities. Their philosophy extended past simply providing quality skylights to the public, but rather provide a higher level of design support services and a level of customer care that was not easily found in the roofing and construction industry at the time. So, Artistic Skylight Domes was born and the journey begins. Taking orders in the morning, producing product during the day, and delivering to customers in the evening, the struggles of entrepreneurship was all too real for our founders.

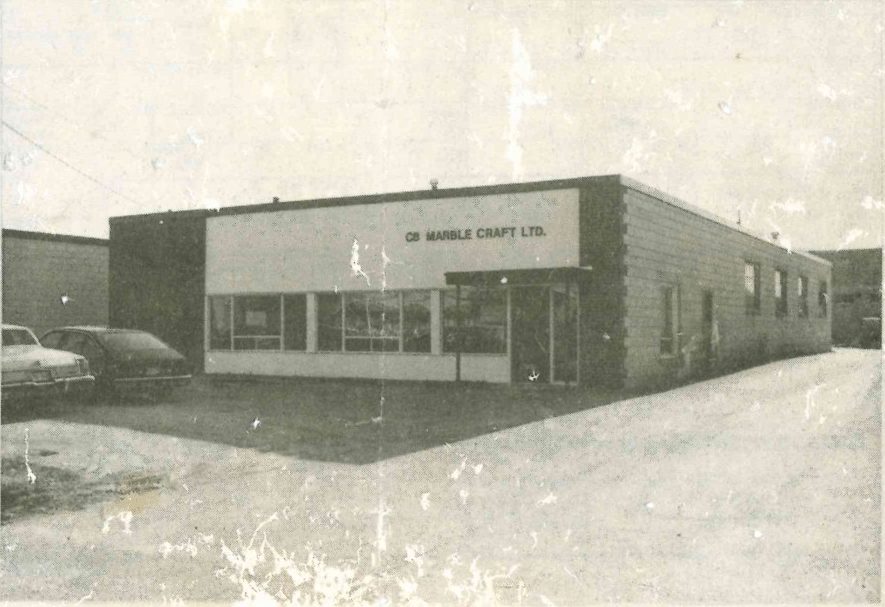

First Location – Nashua Dr.

Upon the conception of Artistic Skylight quickly followed our very first location in Mississauga on Nashua Dr. Our humble 3,200sqft. facility is where we started this amazing journey. At this time, we were only producing curb mounted and self flashing skylights comprised of aluminum and acrylics. Some miscellaneous skylights were also produced but not a mainstream product offering.

Introduction of our PVCCM Model Line

With the growing technology and chemical compounds in the world of PVC, this material quickly became a popular choice for all fenestrations. With higher thermal performance and resistance to mold and rotting, PVC became the basis for our curb mounted skylights. Today, or PVCCM skylights are our by far our most popular product with an all PVC curb frame to create the optimal thermal gap for your skylight.

Major Product Line Expansion

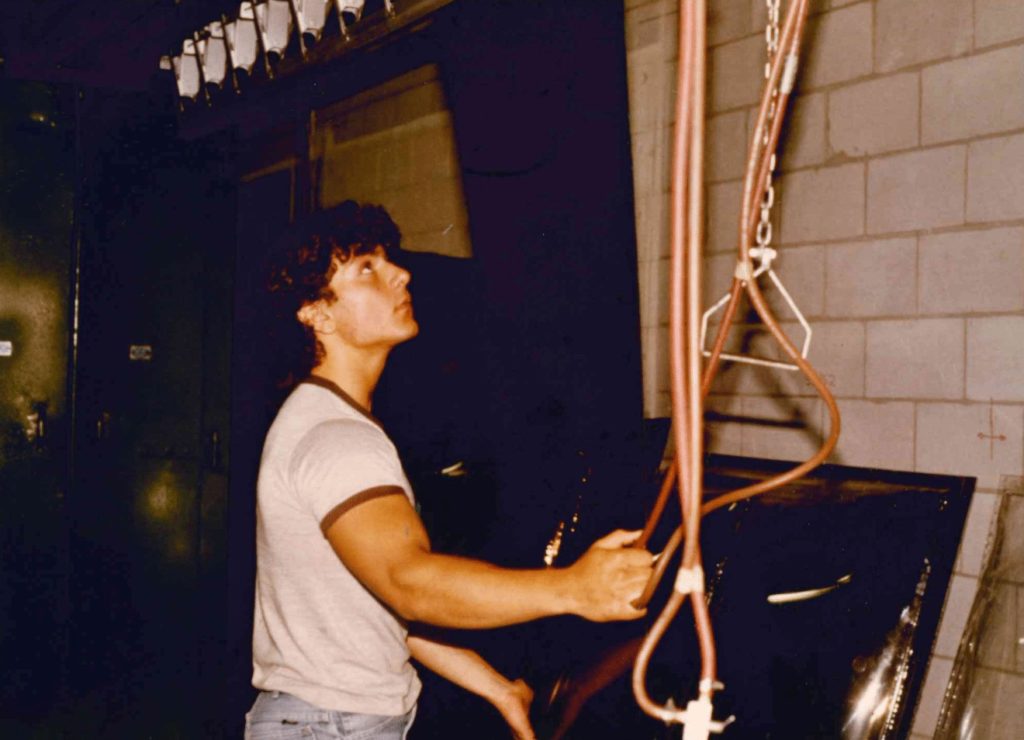

The introduction of glass glazing starts to become a popular trend in the industry and fuels innovation into our current lineup of Glass Skylights and Architectural Structural Glass Pyramid Skylights. And with the increasing trend of pushing the envelope for aesthetically pleasing skylights, our line of Circular Unit Skylights became an immediate success for the industry. Still to this day Artistic Skylight Domes is one of the few companiehttps://artisticskylight.com/products/commercial/structural-architectural-skylights/architectural-glass-continuous-ridge-pyramid-ridge/s actually producing circular skylights. The creation of these new products opened up the firm to new commercial-scale projects highlighting our skills as a niche skylight manufacturer.

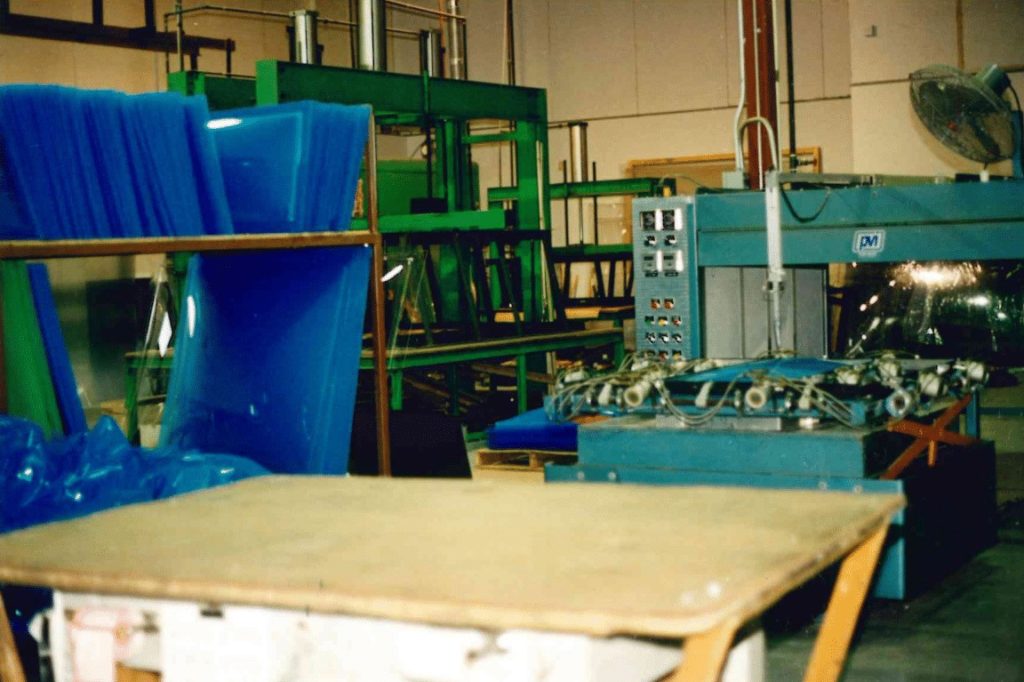

Introduction of Automatic Thermoforming

With the evolution of our curb mounted skylights and a boom in skylight popularity, demand for larger quantities of product quickly grew. To keep up with demand of our acrylic dome skylights, the introduction of an automatic thermo-former was brought to the production floor. A flat sheet of acrylic would be placed into the bed of the machine, heated and formed into our iconic dome shaped skylight. This small but mighty PVI was capable of producing almost 100 formed acrylic domes per work shift. This very same machine is still in service today.

Third Location – 2 Guided Crt.

Through the years, the Artistic Skylight Domes team steadily grew to meet an ever expanding demand. With the rapid expansion seen in through the early stages of the company, a larger 14,000sqft. building and our already our third location at 2 Guided Crt. in Etobicoke was secured and would be home to Artistic Skylight for the next 2 decades. Large factory expansion coupled with new cutting edge machinery, wider ranges of product lines and higher quality products all amending to the modern day success of a small sized company.

New Aluminum Frame Colour Option – Commercial Bronze

With newer trends in the aluminum and fenestration world, the introduction of what is now know as our Commercial Bronze aluminum frame finish colour. With all our current mill finish products being tig welded together, it was important to develop a corner key system that would allow seamless and aesthetically pleasing corner connections of our frames.